Hoist Trolleys

Milwaukee, Wisconsin Hoist Trolleys

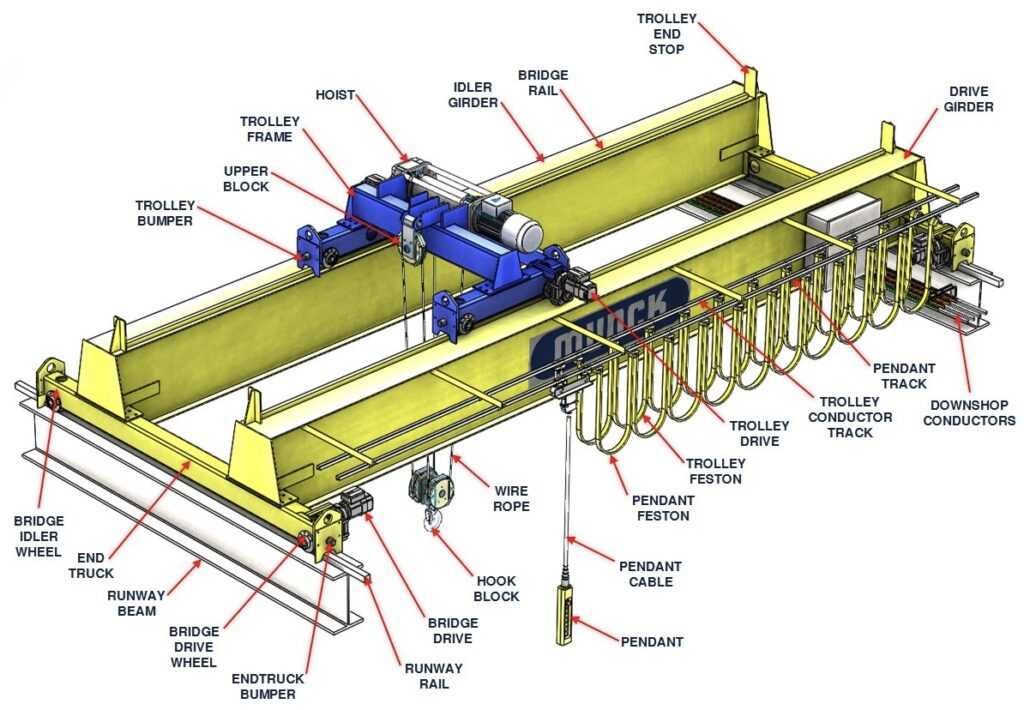

Double Girder Overhead Crane

The components of a double girder overhead crane are essential for its operation and efficiency. Here’s a breakdown of the main parts:

Two Main Beams: These provide the structural support for the crane and allow the trolley to move back and forth across the span.

End Trucks: Located at both ends of the main beams, they house the wheels that enable the crane to travel along the runway.

Cross Travel Rails: These are mounted on top of the girders and guide the trolley’s movement along the length of the crane.

Crane Drive: This mechanism powers the movement of the crane along the rails.

Controls: The operator uses these to control the crane’s movements and the hoisting of loads.

Hoist Trolley: This component, which includes the hoist, is responsible for lifting and lowering loads. It travels along the cross-travel rails.

Material Handling Systems

A hoist trolley is a key component in material handling systems, particularly in conjunction with overhead cranes. Here’s a detailed description:

Function: A hoist trolley is designed to move along a track or rail system, typically mounted on I-beams or W-beams, to transport heavy loads horizontally within a facility.

Composition: It usually consists of a frame that houses wheels or rollers, which can be flat or tapered to accommodate different beam types.

Operation: The trolley can be operated manually with a push trolley, gear operated with a hand chain, or powered by a motor-driven system.

Integration with Hoists: The trolley supports a hoist, which is a mechanical device used to lift and lower loads. The hoist includes a motor, gearbox, brake system, and a lifting mechanism such as a chain or wire rope.

Power Sources: Hoists can be powered by electricity, air, or hydraulics, depending on the specific requirements of the operation.

Together, the hoist and trolley system provide a flexible and efficient solution for lifting and transporting heavy objects, making it an invaluable asset in industrial settings like manufacturing plants, construction sites, and warehouses.

Hoist Trolley Movements

A hoist trolley works by combining both horizontal and vertical movement to transport and lift loads within a manufacturing facility or similar setting. Here’s how the system operates:

Horizontal Movement: The trolley is equipped with wheels that run on rails or beams, allowing it to move back and forth along the span of the overhead crane. This movement is typically powered by an electric motor, although manual and air-powered options are also available.

Vertical Movement: Attached to the trolley is a hoist, which is responsible for lifting and lowering the load. The hoist includes a motor, gearbox, brake system, and a lifting mechanism such as a chain or wire rope. When the hoist motor is activated, it turns a drum or lift-wheel around which the lifting medium (chain or wire rope) is wound, raising or lowering the attached load.

Control System: The operator controls the trolley and hoist using a pendant, radio remote, or cabin controls. These allow precise manipulation of the load’s position and height, ensuring safe and accurate placement.

Safety Mechanisms: Hoist trolleys are designed with various safety features, such as brakes to hold the load securely when not in motion and overload protection to prevent lifting beyond the trolley’s capacity.

The combination of these elements allows the hoist trolley to function as an efficient and versatile tool for material handling, contributing to the productivity and safety of operations where heavy lifting is required.

Here are some manufacturers known for producing hoist trolleys:

Harrington Hoists: They offer a variety of electric trolleys, including motorized and air-powered options suitable for different industrial applications.

Columbus McKinnon: A leading manufacturer providing a wide range of hoisting equipment, including trolleys.

Elephant Lifting Products: Known for their durable and reliable lifting products, including hoist trolleys.

Yale: Offers a comprehensive line of lifting products, with hoist trolleys being among their specialties.

Wesco Industrial Products, LLC.: Specializes in a variety of material handling equipment, including hoist trolleys.

The David Round Co., Inc.: Offers custom-engineered hoisting solutions, with trolleys tailored to specific applications.

New Day Packaging Products: Provides a range of hoist trolleys suitable for different industrial needs.

Ace Industries, Inc.: A provider of high-quality hoists, cranes, and trolley systems with a focus on customized solutions.

Fulcrum Lifting: Distributes electric chain hoists and motorized hoist trolleys from brands like Harrington Hoists and Yale.