Applications

Crane applications near Milwaukee, Wisconsin

Paper cranes in industries and applications

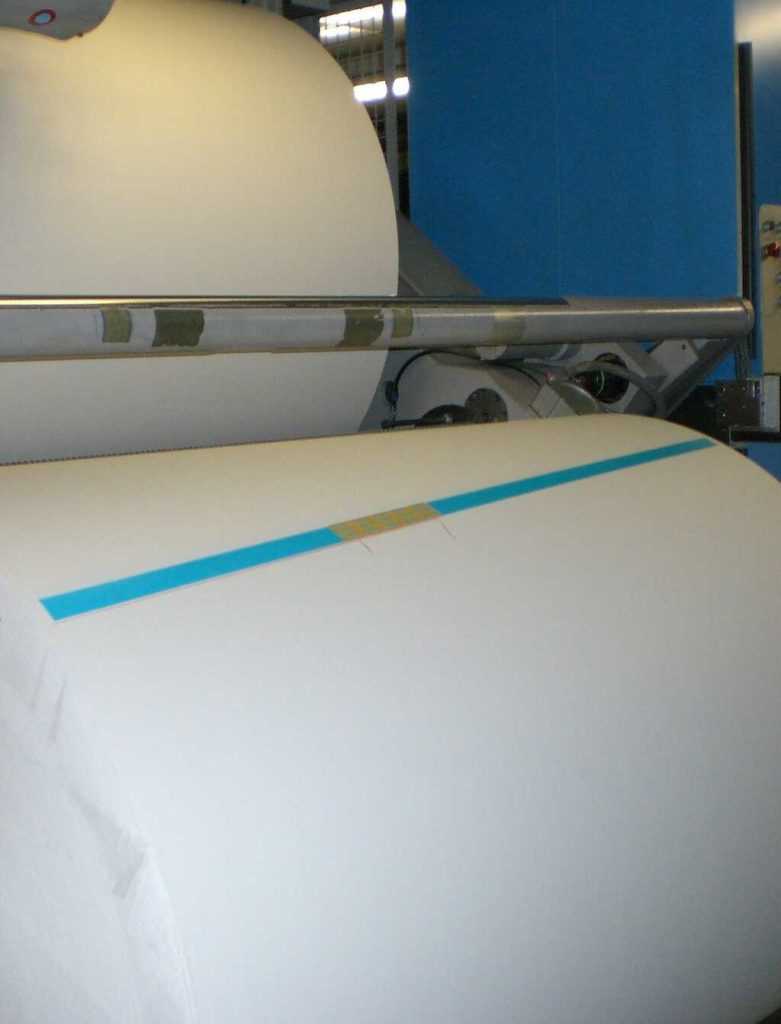

Cranes used in the pulp and paper industry are an integral part of the production process and maintenance. There are several areas to consider when choosing the best crane for your use.

- Range of product use – Low capacity maintenance to automated systems for storage and retrieval

- Task of the crane – rotating spreader/beams, log grabs & paper, reel vacuum lifters

- Applications – wet, dry end, reel & roll handling, automatic shipping roll storage and intermediate roll storage, sheet cutters roll storage.

Cranes in paper factories must operate reliably and correctly around the clock as production downtimes cause high costs. The use of cranes for positioning paper reels weighing several tons precisely is one of the most demanding applications in crane technology.

Die Handling Cranes

Die Handling Cranes are used to manage heavy loads and short cycle for warehouse use. They are commonly used in Automotive Stamping. Use of this crane can be operated in three ways; Manual, Semi-Automatic, Automatic. The major advantages to Automated Die Handling cranes are that they allow for minimal human assistance, reduces errors and reduced wear and tear and time.

Vertical Die Handling cranes are another option and are frequently used in Press Shops. They reduce non-essential handling when reusing the same stamp dies. They free up facility floor space and can maximize production volume for operations. Store items can be protected and reduce tool machining costs.

The benefits of the correct Die Handling Crane can greatly assist your operations in all areas.

Looking beyond the crane to into warranty, maintenance and parts programs. Points to look at are maintenance, safety, productivity, revenue.

Questions to ask

- Are spare parts readily available?

- Are inspections based on industry standard regulations?

- Are Service visits reviewed with you?

- Are maintenance and service records available on line?

- Is updated training provided by your service technician?

Five areas to consider with Die Handling Cranes:

Environment

Temperature, Building Dimensions, what type of crane – Manual, Semi-automatic or Automatic best suits your needs. Are your facility floors strong enough to support multiple stacked dies?

What are your duty classifications?

Is your range infrequent service or continuous severe service. Load and data cycle can help to determine duty class.

Lifting Needs

What is your current crane production, how will changes in future impact what type of crane you need now & in the future. Smart Features on a crane add intelligence using purpose-built software and hardware. Crane control options to consider are; Sway Control, Active Sway Control, Target Positioning, Protected Areas, Hook Centering, Snag Prevention, Micro speed.

Which hook attachment best suits your needs?

Some options are; Dies & Coils-Slings, Coils-C-hook, Coil Magnet or Coil Grab. Press areas include; Slings-chains, lifting beam with slings-chain on every corner, Die gripper.

How many sets of below-the-hook lifting devices are used in an operation?

Two more below-the-hook options are; Up-Enders or motorized flipping devices are used to rotate or turn large dies or rotate coils safely. Choosing the correct attachment(s) will enhance your productivity and production safety. Die Horses can be engineered to your specific die handling process for safety and compliance with industry standards.

Steel industry cranes and applications

Iron and steel foundries require high reliability, durability and safety of load handling, therefore, the crane and its parts are developed to meet the highest standards. Cranes used in this environment need to be designed to transport hot liquid steel in harsh environments with extremely high temperatures putting significant stress on the crane and its components.

There are several things to identify when selecting the correct overhead crane for you selecting the right overhead crane for your application:

- The type of crane you need (single girder or double girder)

- Rated load capacity

- Span

- Lifting height

- Lifting speed

- Duty cycle

- Control mode (remote control or cabin control)

- Power source

- Do you need a runway? If it is, what is the length of the runway?

- Other special requirements

Manufacturing

Cranes in manufacturing and application

Metal Manufacturing

Cranes are used for moving crucibles of molten ore or loading rolls of finished sheet. Metal workers require overhead cranes to handle the weight as well as the elements – metals at dangerous temperatures. Overhead cranes can do this work and help keep workers at a safe distance from dangerous materials. Specialized attachments such as C-hooks can help move spools of wire and foil, too.

Concrete Manufacturing

The concrete industry is neither small nor light. Workers need gantry cranes in the yard and bridge cranes in the factory to handle bagged premix or finished precast. Pouring architectural spans requires the power and control of an overhead crane.

Power Plants

Power plants are filled with working equipment that must remain functioning 24/7 avoiding downtime & blackouts. When a turbine or generator inside an active plant needs service, it must be removed and replaced with care. A precise bridge crane system is essential for this service.

Ship building

A wide-spanning heavy gantry crane is a must for building ship hulls. Ship hulls are massive and irregularly shaped. Moving heavy tools and parts around the inside of a slanted hull can be impossible without an overhead crane.

Plastic Injection Molding

The plastic fabrication industry involves heavy weights & high temperatures. Safety and precision demand a strong and agile system of overhead cranes. Elements to consider include – melted ingredients, raw materials, and finished products which must be handled with care and dexterity. This is where the need for overhead cranes comes in.

Automotive

Bridge cranes are ideal for auto assembly lines providing reliable movement of their product from station to station on its journey to completion. Gantry cranes can be used for auto repair for jobs such as pulling engines and lifting car bodies. Automation of these complex systems of machinery require a programmer to help operate and maintain the cranes.

Save Money,

Eliminate down time

Quality is and always has been, our number one priority. We have built our reputation by offering products with an uncompromising commitment to quality, reliability and customer service.

Military / Government Cranes and Applications

Cranes for Military require special technical considerations. The equipment versions for military cranes may include the following, depending on requirements/applications:

- Rescue winches

- Towing hitches

- Tires with emergency features

- Emergency hydraulic controls

- Various load handling equipment

- Special containers for transporting special accessories

Crane solutions are available for transport, material handling and recovery for both wheeled & tracked vehicles in support of the widest variety of military projects and applications throughout the world. Loader cranes are suitable for mounting on all chassis types, e.g. for repair and maintenance applications, as a classical material handling crane, bridge-laying crane and recovery crane.

Shipping cranes & applications

A wide-spanning heavy gantry crane is a must for building ship hulls. Ship hulls are massive and irregularly shaped. Moving heavy tools and parts around the inside of a slanted hull can be impossible without an overhead crane.

A container crane (also container handling gantry crane or ship-to-shore crane) is a type of large dockside gantry crane found at container terminals for loading and unloading intermodal containers from container ships.

Container cranes consist of a supporting framework that can traverse the length of a quay or yard on a rail track. Instead of a hook, they are equipped with a specialized handling tool called a spreader. The spreader can be lowered on top of a container and locks onto the container’s four locking points (“corner castings”) using a twistlock mechanism. Cranes normally transport a single container at once, but some newer cranes have the capability to pick up two to four 20-foot containers at once.

A modern container crane capable of lifting two 20-foot (6.1 m) long containers at once (end to end) under the telescopic spreader will generally have a rated lifting capacity of 65 tons. Some new cranes have a 120-ton load capacity, enabling them to lift up to four 20-foot (6.1 m) or two 40-foot (12 m) containers .

ADVANTAGES AND BENEFITS

- High performance cranes with a lower self-weight and center of gravity

- Increased productivity compared with alternative designs

- High reliability and low downtime

- Rigid and stable structure

- Improved performance where high in-service winds prevail

- Accurate spreader positioning

- Anti-sway reeving

- Optimum driver comfort due to ergonomic cabin and unique Liebherr hinge point design

- Precision simultaneous drive motion in three axis

- Low lifecycle costs

Mining cranes & applications

Mining cranes serve multiple purposes, deal with several different environmental elements and have special requirements. They include the following:

- Require efficient handling of very heavy and sometimes hazardous loads

- Operation in extreme environmental conditions; heat, vibration, abrasive dust, moisture and heavy-duty usage, explosive gases. Can cause corrosion and premature wear/tear.

- Cranes can be customized to meet specific needs including low headroom/maneuver in tight spaces, spark and corrosion-resistant construction, explosive proof

- Durability and safety of crane, prevent crane accidents

Types of cranes that work best in this field are – Overhead, Gantry, Jib, Single & Double Girder. Hoists include – Chain and Wire Rope. Mining Winches. Automatic controls assist in easier operator control. Protection components are put in place to protect operator.

Automotive

Bridge cranes are ideal for auto assembly lines providing reliable movement of their product from station to station on its journey to completion. Gantry cranes can be used for auto repair for jobs such as pulling engines and lifting car bodies. Automation of these complex systems of machinery require a programmer to help operate and maintain the cranes.